Chemical etching, a sophisticated and precise metal processing technique, has become a cornerstone in various industrial sectors. By selectively removing material from metal surfaces, chemical etching offers unparalleled precision and flexibility, making it a go-to solution for crafting intricate metal components. In this article, we delve into the wide-ranging industrial applications of chemical etching, uncovering its impact on industries such as aerospace, electronics, automotive, and beyond.

Aerospace Advancements: Crafting High-Precision Components Chemical etching has emerged as a critical technology in aerospace manufacturing. It enables the creation of intricate and lightweight components used in aircraft and spacecraft. Explore how chemical etching contributes to weight reduction, fuel efficiency, and the overall performance of aerospace systems.

Electronics Evolution: Precision Circuitry and Connectors The electronics industry relies on chemical etching to produce intricate circuit patterns, connectors, and contacts. Delve into how this technique facilitates the production of high-density circuit boards, flexible electronics, and miniaturized components crucial for modern devices.

Automotive Engineering: Enhancing Performance and Safety Chemical etching plays a pivotal role in automotive engineering by producing precise metal components used in fuel injection systems, airbags, sensors, and more. Discuss how chemical etching contributes to improving vehicle performance, safety standards, and fuel efficiency.

Medical Devices: Enabling Cutting-Edge Healthcare Solutions Explore how chemical etching contributes to the medical field by producing intricate components for diagnostic devices, implants, and surgical instruments. Highlight its role in ensuring biocompatibility, sterilization, and accuracy in medical equipment.

Renewable Energy: Precision in Sustainable Technologies Chemical etching is instrumental in the production of components for renewable energy technologies, including solar panels and fuel cells. Discuss how its precision contributes to the efficiency, durability, and cost-effectiveness of these sustainable energy solutions.

Defense and Security: Precision in Mission-Critical Systems Investigate the use of chemical etching in producing mission-critical components for defense and security applications. From precision optics to sensor systems, explore how chemical etching ensures reliability and accuracy in these demanding environments.

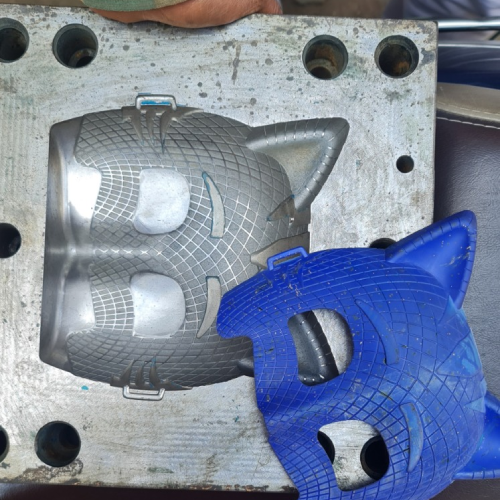

Industrial Machinery: Enhancing Performance and Durability Chemical etching plays a key role in manufacturing industrial machinery components such as gears, blades, and molds. Detail how this technique enhances wear resistance, corrosion protection, and overall longevity of machinery.

Jewelry and Fashion: Elevating Aesthetics with Precision Beyond industrial applications, chemical etching is utilized in crafting intricate jewelry and fashion accessories. Showcase how this technique adds artistic flair to metal creations, allowing designers to realize complex patterns and textures.